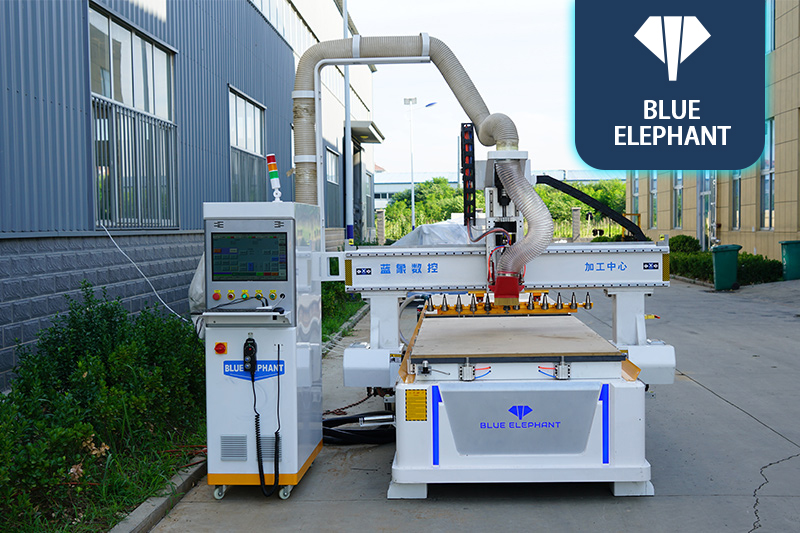

At present , the CNC cutting machine is widely used. In the production of panel furniture, it can not only process various special-shaped patterns, but also has a good cutting effect on special-shaped plates. It can better realize the functions of cutting, punching, slotting, etc., but there is also a problem that needs special attention when purchasing equipment, which is the problem of price differences. Do you know the reasons for the difference in the price of the cutting machine? How much do you know about this? Next, Blue Elephant CNC will give you a detailed summary.

However, many furniture manufacturers tend to fall into the price trap when purchasing CNC cutting machines and choose low prices, ignoring the following important factors.

1. The spindle power of the CNC cutting machine directly affects the processing efficiency of the cutting machine. If you need to cut thick plates, it is recommended to use a high-power spindle.

2. The CNC feed motor is basically a stepper motor. If you want to slightly improve the following performance, you can choose a domestic servo motor. Shangjia is configured as an internationally renowned brand of servo motor products. There is also a huge price gap between the two.

3. The main shaft of the cutting machine is divided into air cooling and water cooling. Air-cooled and water-cooled are louder than water-cooled. If a water-cooled vacuum pump is used, the antifreeze problem of the vacuum pump in autumn and winter should be considered.

4. The key is the cutting machine software. If there is a need in this regard, you can buy genuine software or pirated software. Although genuine software is expensive, it can be upgraded, and pirated software can be used, but cannot be upgraded.

Regarding the reasons for the price difference of the CNC cutting machine , the above content has been introduced to you. From this, we understand that the main reasons for the difference in the equipment are the spindle power of the equipment, the performance of the stepping motor, the cooling method of the spindle and the cutting machine. Software and other four aspects, I hope everyone will not get lost because of some petty profits when purchasing.