CNC Router with automatic edge banding machine can achieve the effect of fast cutting and edge sealing, greatly improving the quality of processing, mainly used in cabinet processing, So do you know what kind of effect the combination of the two will have? How much do you know about it? Let’s take a look with Blue Elephant CNC!

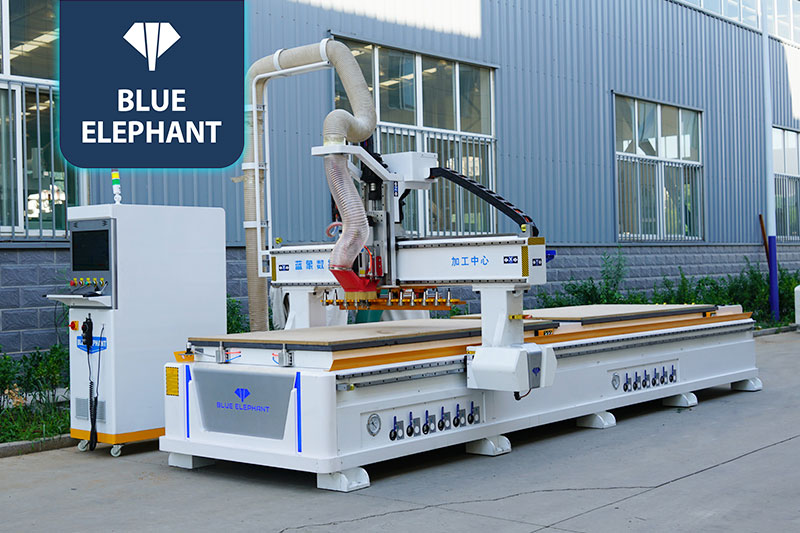

First, CNC Router – straight row automatic tool changing Router

In-line automatic tool changer and Router is a woodworking CNC Router for the production of panel furniture, cabinets, wardrobes and engraving cabinet door panels. ;Compared with the previous panel saws, the cutting section is smoother and free of burrs, and it can process square-shaped panels, as well as special-shaped panels, such as blanking of panels with missing corners or arc shapes, especially It is suitable for the production of customized furniture for the whole house.

The specific features are as follows:

12 in-line tool changers, multiple knives can be switched freely, and the process is more concise;

Adopt mobile tool setter to reduce machine downtime;

The full-page vacuum adsorption table has strong adsorption force and does not run off the plate during processing;

Adopting a new type of large bed structure, the bed is more stable and the bed has a strong load-bearing capacity;

One-key start-stop, positioning, more convenient after loading, and increase work efficiency;

Suitable for panel furniture production lines, cabinet doors, wood engraving, circuit board engraving, milling, musical instruments, etc.;

The in-line automatic tool changer and opening machine is equipped with six-sided drilling, edge banding machine, laminating machine and other panel furniture production equipment.

Second, Automatic edge banding machine

Main functions: pre-milling – glued welt 1 – six rounds of pressing – baking light 1 – glued welt 2 – six rounds of pressing – baking light 2 – front and rear alignment – fine trimming 1 – fine trimming 2 – tracking trimming – Pneumatic scraping – flat scraping – pneumatic polishing 1 – pneumatic polishing 2 – screen one-button control before and after cleaning.

Scope of application: suitable for panel furniture, custom furniture, cabinets and wardrobes, office furniture, solid wood furniture, tables, chairs, doors and windows, wood products, decoration and decoration industries, etc.

Machinable board: suitable for MDF, ecological board, multi-layer board, particle board, straight solid wood board, aluminum honeycomb board and other boards.

CNC Router and automatic edge banding machine are important equipment for making cabinets, which can solve many sheet problems without wasting sheets. We also listed the functions of the equipment in the above content. If you have a new understanding and understanding of this, friends in need can also consult us.