(Upgraded) Panel Furniture Production Equipment Solution

It can meet the production and processing of whole-house custom manufacturers, with flexible machine combinations and variable processes, creating an automated production mode that meets the needs of customers’ entire factories.

Features

►(Upgraded) Panel Furniture Production Equipment Solution

Cabinet body/cabinet door (blister/flat) production solutions are mainly composed of straight row tool changer machining center, edge banding machine, side hole machine, polishing machine, laminating machine, precision saw, stacking arm edge banding machine, double spindle hinge It is composed of drill and metal strip cutting machine, which can meet the production and processing of whole-house customized manufacturers. The machine combination is flexible and the process is changeable, creating an automatic production mode that meets the needs of the customer’s entire factory.

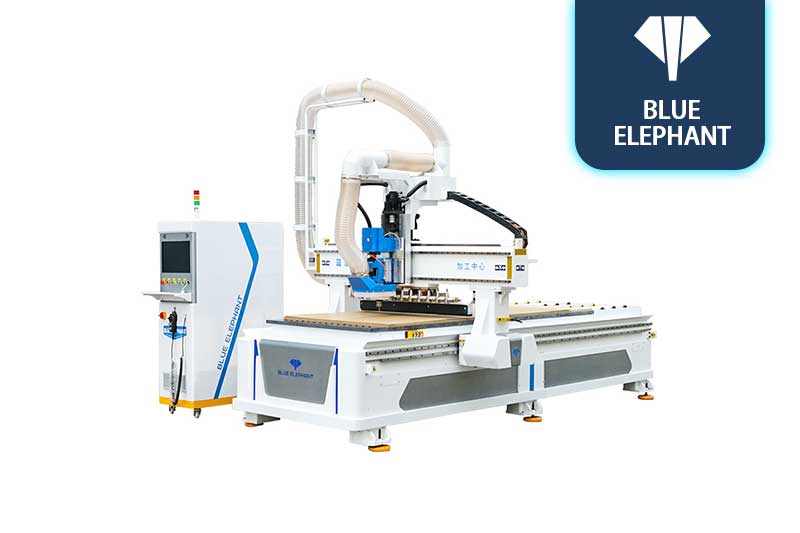

►In-line tool change machining center

Introduction: The in-line automatic tool changing machining center can carve wood products such as furniture, wooden doors, cabinets, tables, chairs, doors and windows. It has an independent tool magazine and can automatically replace the required tools during the processing of the workpiece without stopping work.

Features:

1. It is suitable for multi-complexity product processing or various processing, with a wide range of functions, such as drilling, cutting, side milling, chamfering, etc.

2. All the mechanical and electrical components of this model are of international famous brands.

3. In-line automatic tool change, the tool magazine capacity is 12 tools, the tool change time is fast and the efficiency is high.

4. Strong software compatibility.

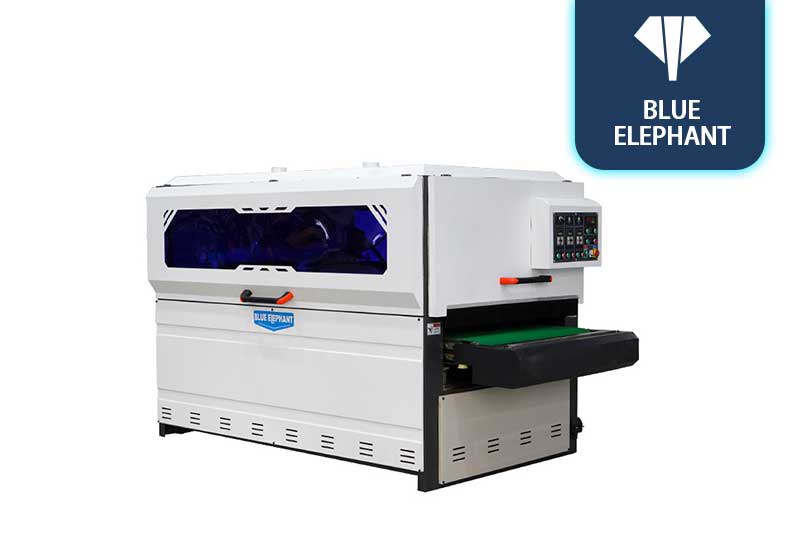

►Edge Banding Machine

Introduction: Scope of application of edge banding machine: suitable for panel furniture, custom furniture, cabinets and wardrobes, office furniture, solid wood furniture, tables, chairs, doors and windows, wood products, decoration and decoration industries, etc. board, particle board, straight solid wood board, aluminum honeycomb board and other boards.

Features:

1. Function of edge banding machine: gluing and welting → front and rear alignment → rough trimming → fine trimming → tracking trimming → scraping edge → polishing.

2. Glue and seal the edge: the air cylinder controls the opening and closing of the glue door (WSN cylinder and billion-day solenoid valve), the glue quantity is stable, and the thickness is uniform.

3. Front and back: Cut off the excess edge banding at both ends of the sheet (WSM cylinder with 2 pressure regulating valves and 1 pressure relief valve) The air pressure is more stable, and the head and tail are more stable.

4. Rough repair: The six-edged alloy flat knife trims off the excess edge.

5. Refined trimming: The six-blade R knife trims off the excess edge banding strips to form rounded corners, and the trimming is more beautiful.

6. Profile tracking: The four corners after edge sealing are trimmed into small arcs to be more smooth and not irritating. The self-designed tracking action and air path design make the profile and chamfering action more stable.

7. Scraping the edge: the super hard alloy R knife scrapes the fine lines of the edge banding strip to make it smooth.

8. Polishing: The cloth wheel quickly polishes and polishes the edge of the edge band, which is smoother and more beautiful.

►Side hole machine

Introduction: The side hole machine is designed and developed for the panel furniture wardrobe. It is suitable for the design of cabinet wardrobes and panel furniture. It can complete the three-in-one side hole/wood pin hole/blind hole/fixed slot/through slot/four kinds of hidden parts. Punch holes on the side.

Features:

1. Intelligent punching, no need to pay attention to the size and placement direction of the board, accurate positioning by laser scanning, and intelligent judgment of the punching position.

2. There are customized limit, high safety protection.

3. There is no need to scan the barcode, just put it and punch it, and it is convenient and quick to scan the hole and punch the hole.

4. A variety of punching modes can be freely switched to meet various process requirements.

►Polisher

Introduction: The polishing machine is suitable for all kinds of solid wood, MDF, iron sheet and other materials. Ideal equipment for the production of opposite-sex polishing of doors and windows, cabinet furniture, etc.

Features:

1. Surface processing equipment for wood products, mainly for rough grinding and primer polishing of wood products.

2. Using frequency conversion speed regulation, the speed can be adjusted freely to select the appropriate feeding speed to ensure the polishing quality of the workpiece.

3. The sanding roller is composed of sisal brush and gauze. It can provide various combinations of gauze and brush, and the gauze and brush can be replaced respectively, saving cost.

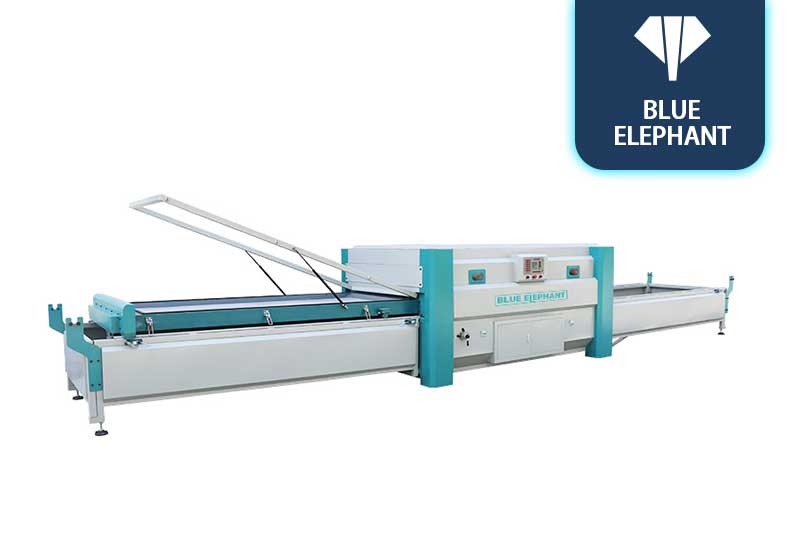

►Laminating machine

Introduction: The laminating machine can make three-dimensional lamination of various PVC films on various materials such as furniture, cabinets, speakers, and paint-free doors.

Features:

1. The body of the equipment is welded and processed with high-quality steel. The force point is strictly calculated, and the stability without deformation is high.

2. The heating system adopts a microcomputer temperature controller, which can be automatically controlled according to the temperature change, so as to adjust the heating speed to achieve the purpose of controlling the temperature.

3. Using automatic digital display technology The whole machine has a high degree of automation, simple operation and low failure rate.

Reviews

There are no reviews yet.