(High-end) Panel Furniture Production Equipment Solution

Suitable for diversified complex product processing or diverse processing.

Features

►High-end type – panel furniture production equipment solution

The high-end panel furniture production equipment scheme is mainly composed of three large equipments, such as in-line tool changing machining center, edge banding machine and six-sided drilling machine, as well as supporting machines such as precision saw, stacking arm edge banding machine, double-spindle hinge drill, and metal strip cutting machine. , which can meet the production and processing of whole-house custom manufacturers, with flexible machine combinations and variable processes, creating an automated production mode that meets the needs of customers’ entire factories.

CNC cutting equipment (straight machining center) can be equipped with automatic labeling machine, which is mainly used for the production and processing of panel furniture and cabinet door panels, grooving, engraving and cutting blanking processing, processing common panel furniture two-in-one, three The installation hole position of the integrated connector has the function of processing some types of invisible connectors. It is suitable for the processing of diversified and complex products or various processing. It has a wide range of drawings and can be blanked, drilled, cut, engraved, etc. at one time, especially suitable for customization. It can meet the needs of production and processing, with CNC six-sided drilling, front-end intelligent automatic labeling and efficient cutting and blanking, no need for turning plate processing, automatic queuing and continuous processing, simple operation, high production capacity, labor saving and other advantages.

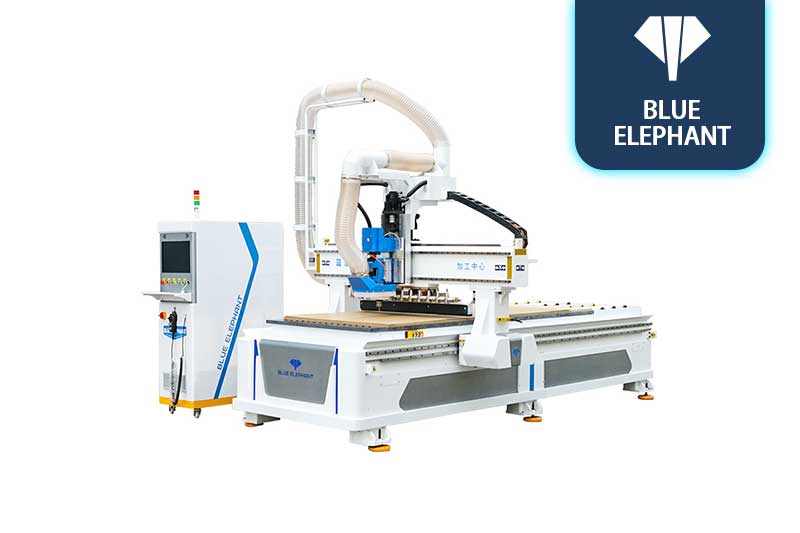

►In-line tool change machining center

Introduction: The in-line automatic tool changing machining center can carve wood products such as furniture, wooden doors, cabinets, tables, chairs, doors and windows. It has an independent tool magazine and can automatically replace the required tools during the processing of the workpiece without stopping work.

Features:

1. It is suitable for multi-complexity product processing or various processing, with a wide range of functions, such as drilling, cutting, side milling, chamfering, etc.

2. All the mechanical and electrical components of this model are of international famous brands.

3. In-line automatic tool change, the tool magazine capacity is 12 tools, the tool change time is fast and the efficiency is high.

4. Strong software compatibility.

5. Optional automatic loading and unloading platform, automatic labeling machine and other configurations.

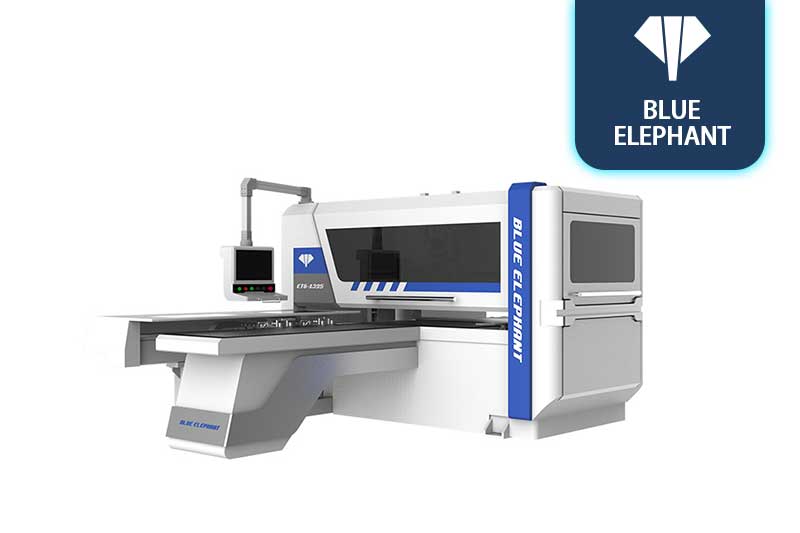

►Automatic edge banding machine

Introduction: Scope of application of edge banding machine: suitable for panel furniture, custom furniture, cabinets and wardrobes, office furniture, solid wood furniture, tables, chairs, doors and windows, wood products, decoration and decoration industries, etc. board, particle board, straight solid wood board, aluminum honeycomb board and other boards.

Main functions: pre-milling – glued welt 1 – six rounds of pressing – baking light 1 – glued welt 2 – six rounds of pressing – baking light 2 – front and rear alignment – fine trimming 1 – fine trimming 2 – tracking trimming – Pneumatic scraping – flat scraping – pneumatic polishing 1 – pneumatic polishing 2 – screen one-button control before and after cleaning.

Scope of application: suitable for panel furniture, custom furniture, cabinets and wardrobes, office furniture, solid wood furniture, tables, chairs, doors and windows, wood products, decoration and decoration industries, etc.

Machinable board: suitable for MDF, ecological board, multi-layer board, particle board, straight solid wood board, aluminum honeycomb board and other boards.

►CNC six-sided drill

The CNC six-sided drill can be directly connected with a variety of dismantling software, and is mainly used for six-sided (hinge hole, through hole, semi-through hole) and horizontal pull grooves of various artificial boards.

1. The system recognizes the processing information by scanning the code, which is intelligent and efficient.

2. Computer operation, CAD drawing, CAM import, can directly import DXF, MPR, xml and other open data formats, easy to operate.

3. Using double gripper guide rails, intelligent detection of hole position information can effectively avoid the opening position, reduce the time of hand change during drilling process, the gripper stroke exceeds 5.5 meters, large panels can be grasped and processed at one time, and large side panels of wardrobes can be drilled. Hole processing time is greatly reduced.

4. Equipped with air flotation worktable and air flotation platen, during the processing process, the upper and lower surfaces of the plate form an air layer, which improves the conveying efficiency of the plate, and at the same time avoids scratching the plate, and the platen drilling is completed at the same time to ensure the drilling accuracy and efficiency.

5. According to the production output and production process, the processing mode can be selected, and the mode is forward and backward. After the plate is processed, the next plate can be processed.

Reviews

There are no reviews yet.