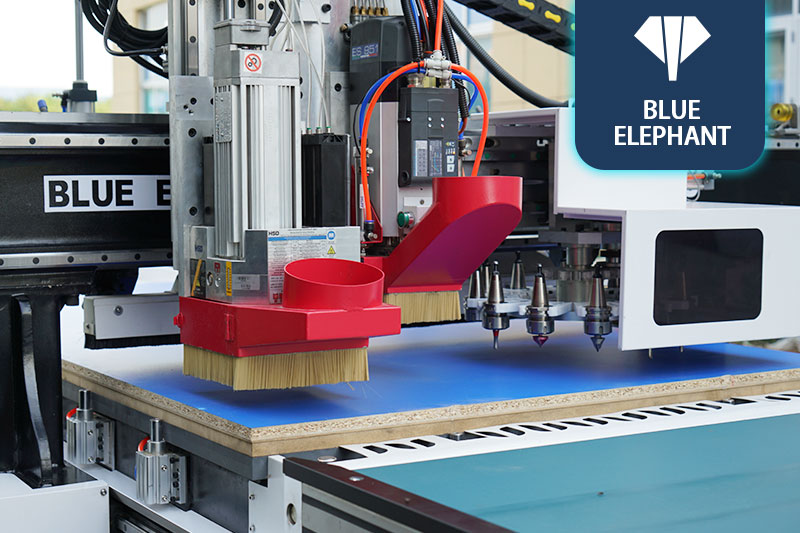

Drilling disc tool changing machining center with loading and unloading platform

At the same time, it can complete automatic feeding, vertical punching, rectangular cutting, special-shaped cutting, troughing, automatic unloading and other processes.

Features

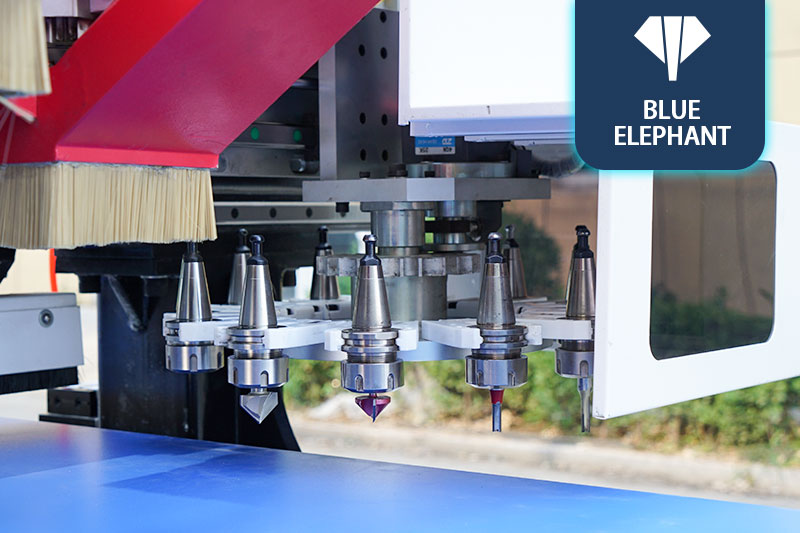

The disc tool changer (12 tool magazines) is used for a full set of automatic loading and unloading, which saves time for loading, unloading and tool changing, and improves production efficiency.

The drill row adopts Italian HSD 9 vertical drill row, which has high precision and high speed.

Cooperate with the disassembly software to achieve optimized layout, save plates, and improve production efficiency.

Vacuum adsorption table, can process different shapes of plates, good adsorption.

At the same time, it can complete automatic feeding, vertical punching, rectangular cutting, special-shaped cutting, troughing, automatic unloading and other processes.

Parameters

| Product name and model | ELECNC1325ATC |

| Three-axis travel | 1300*2500*200mm |

| machine color | Black bed + white sheet metal |

| Chassis Voltage/Frequency | 380V/3 phase/50HZ |

| Spindle power | Italian HSD air-cooled tool changer spindle |

| Spindle cover | have |

| system | New generation 4-axis system + handwheel |

| Inverter | Taiwan Delta |

| Motors and Drives | Yaskawa Servo Motor Yaskawa Drive |

| countertop structure | Whole board adsorption |

| side panel type | Welded side panels |

| guide | PMI 25# square rail |

| Rack/Module | helical teeth |

| Limited brand | Japan Omron limit |

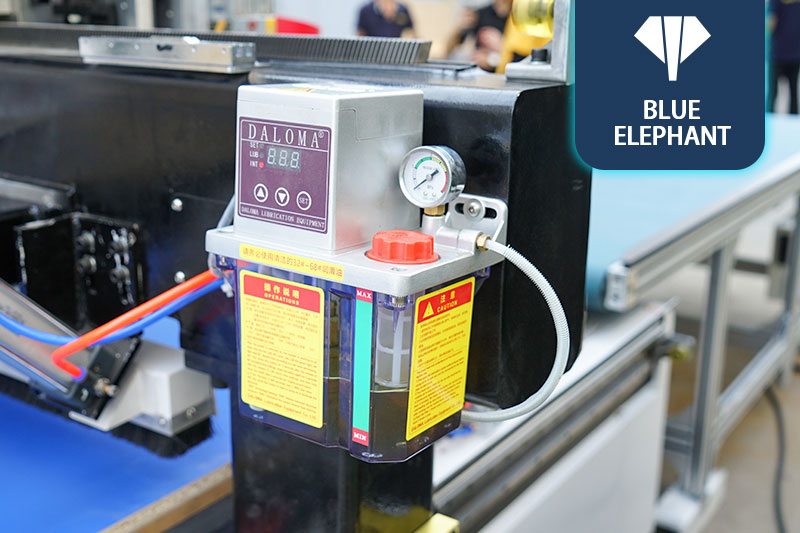

| Lubrication system | Large Electric Gear Lubrication Pump |

| Vacuum cleaner voltage and frequency | New double bag vacuum cleaner, vacuum stand 380V/3 phase/50HZ |

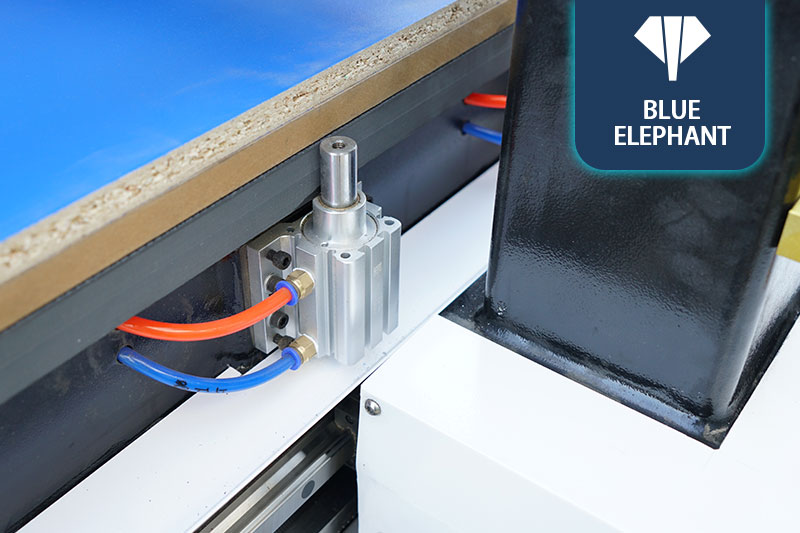

| positioning cylinder | X axis 2 Y axis 5 |

| knife | Automatic tool setter |

| Vacuum Pump Voltage and Frequency | Germany 4kw Baker pump 380V/3 phase/50HZ |

| Chassis (type, color) | Rittal case/black |

Reviews

There are no reviews yet.