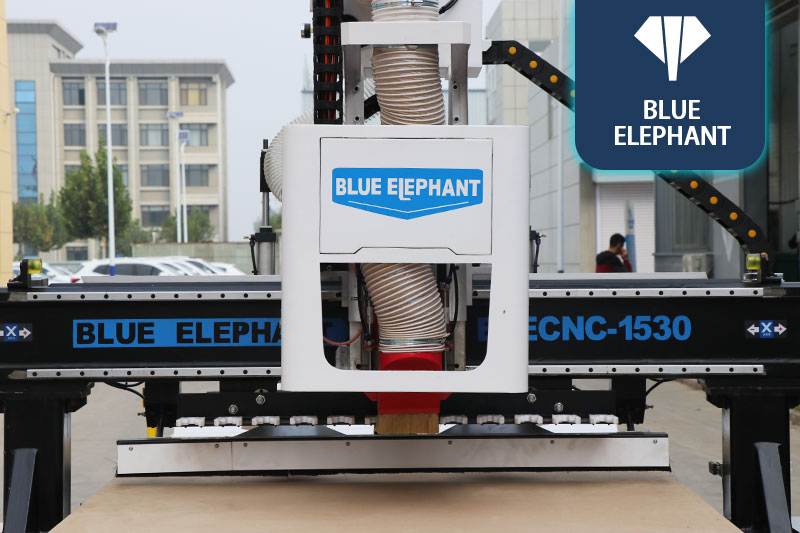

Automatic loading and unloading panel furniture production line

Self-contained pusher device, which automatically pushes the plate from the processing table after processing, which is convenient for the operator to take the material, saves the time of idle work, and has high efficiency.

Features

This machine is: automatic loading and unloading straight row automatic tool change machining center.

Features are as follows:

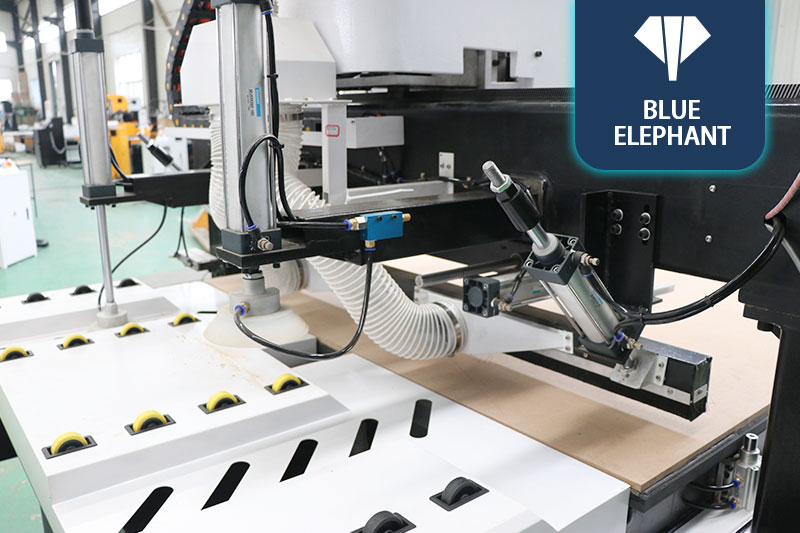

Self-contained pusher device, which automatically pushes the plate from the processing table after processing, which is convenient for the operator to take the material, saves the time of idle work, and has high efficiency.

Realize optimized layout, save plates, and improve production efficiency.

Vacuum adsorption table, can process different shapes of plates.

It can simultaneously complete automatic feeding, vertical punching, rectangular cutting, special-shaped cutting, troughing, automatic unloading, and the operation is simple.

Parameters

| Product name and model | Automatic loading and unloading ATC1530 |

| machine color | black |

| Three-axis travel | 1500*3000*200mm |

| system | new generation |

| Chassis Voltage/Frequency | 220V, 3phase, 60HZ |

| Spindle power/speed | Italian HSD ES951 |

| Inverter | Delta inverter |

| Motors and Drives | Yaskawa Servo |

| reducer | japan new treasure |

| bed structure | large square tube |

| countertop structure | Full page adsorption |

| side panel type | column side panel |

| guide | PMI #30 |

| Rack/Module | J&T helical tooth 1.5M |

| Limited brand | Omron |

| Lubrication system | Electric gear pump |

| Vacuum pump (voltage and frequency) | Double-stage vortex pump (220V, 3phase, 60HZ) |

| Vacuum cleaner (voltage and frequency) | New double bag, (220V, 3phase, 60HZ) |

| positioning cylinder | have |

| knife | automatic tool setting |

| Chassis (type, color) | Rittal large chassis |

Reviews

There are no reviews yet.